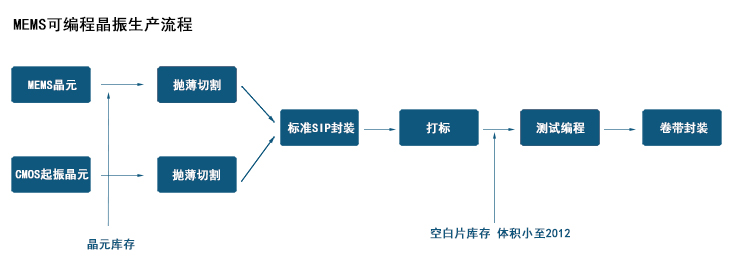

The SiTime crystal oscillator adopts full silicon MEMS technology. It is stacked by two chips, with CMOS PLL driver chips at the bottom and MEMS resonators at the top. It is completed by standard QFN IC packaging. After the packaging is completed, the laser marking process is carried out. Generally, the black crystal oscillator surface is marked with B07CG. Any frequency point of 1-110MHZ can be programmed to six decimal places; Each frequency point can provide 7050, 5032, 3225, 2520 packages, etc

Before burning, the silicon crystal oscillator belongs to a blank piece, and the blank piece is used for burning. According to different customer needs, the program parameters for burning are also different. Again, if you accidentally enter wrong burning parameters or individual parameters are different, the blank piece of the silicon crystal oscillator will be scrapped. Therefore, the customer requires that the parameters should be careful and the staff should repeatedly verify. The burning is divided into manual burning and machine burning. There are many manual burning in China. Manual burning is troublesome, slow, and error prone.

As a first-class agent of SITIME crystal oscillator, it owns the first MEMS silicon crystal oscillator production machine in China, and is also the first programmable crystal oscillator manufacturer in China; One hour mass production of more than 1000 active crystal oscillators, and 1-2 days of rapid delivery in large quantities. (For relevant reading, please refer to the official website “Becoming the first agent manufacturer with fast burning SITE crystal oscillator in China”

MEMS technology can integrate mechanical components, optical systems, driving components and electronic control systems into a micro system of an integral unit. This kind of micro electro mechanical system can not only collect, process and send information or instructions, but also act autonomously or according to external instructions according to the obtained information. It uses the combined manufacturing process of microelectronic technology and micro processing technology (including silicon body micro processing, silicon surface micro processing, LIGA and wafer bonding technology) to produce a variety of high-performance, low-cost, miniaturized sensors, actuators, drivers and microsystems.

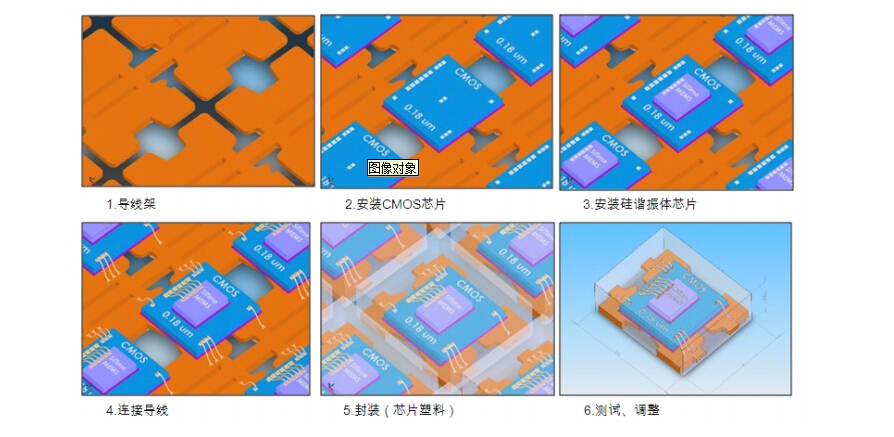

The SITIME MEMS silicon oscillator is composed of a MEMS silicon wafer and a CMOS wafer, while the CMOS wafer includes NON Memory, PLL phase-locked loop circuit, oscillator circuit and temperature compensation circuit.

The above six figures reveal the entire production process of the SITIME crystal oscillator. The SITIME MEMS oscillator uses the superposition of the upper and lower wafers, and the external packaging is made of IC general plastic. It not only greatly reduces the process of quartz crystal oscillator, but also comprehensively improves the product performance.